How To Properly Install A Hydraulic Adjustable Adapter With Locknut.

Adjustable adapters are widely used in hydraulic systems of construction machinery due to their unique advantage of adjustable and positionable oil port direction. The adjustable adapters should be installed in the correct way, otherwise it may cause joint failure, oil leakage, and other faults.

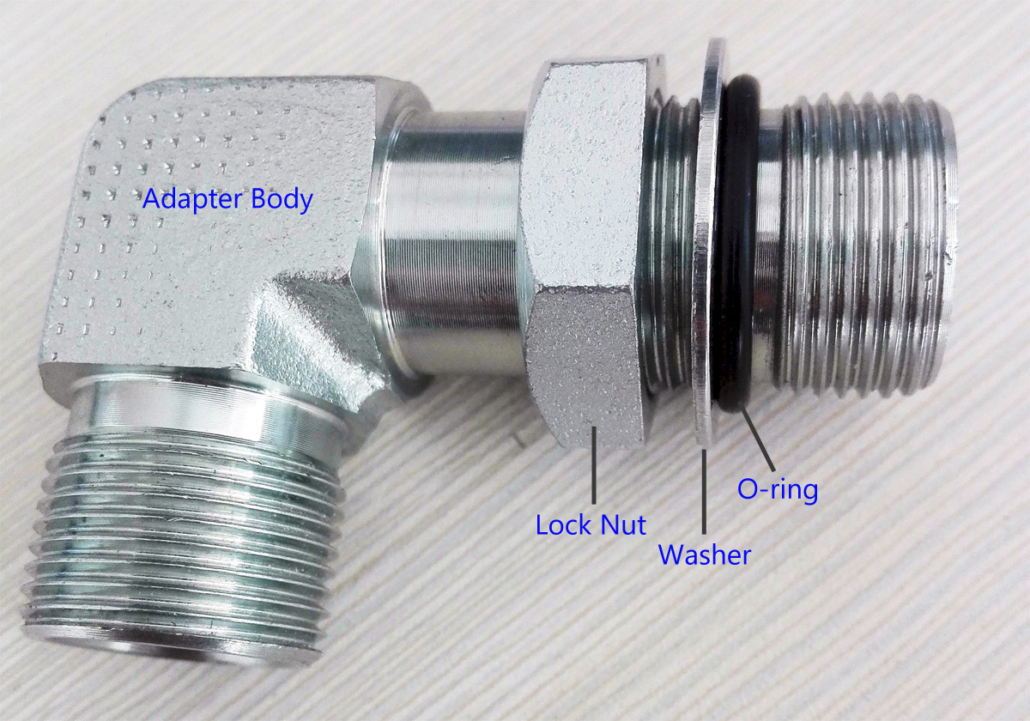

The adjustable adapter’s structure of the O-ring seal is shown in the following diagram:

As shown in the above diagram, the sealing principle of the adjustable adapter is to compress the O-ring with the washer by locknut to achieve the sealing effect. If the washer is deformed due to improper installation method, it will lead to poor sealing effect or sealing failure.

The following is the correct method for installing an adjustable adapter:

①Rotate the lock nut to the left away from the washer, and push the O-ring and washer to the far left, as shown in the above diagram.

② Screw the adapter into the target oil port by hand until it cannot be tightened (do not use a wrench to directly screw the adapter body), and then adjust the direction back to the desired direction.

③ Use a wrench to tighten the locking nut, and the tightening torque should not be less than the torque specified in the “Hydraulic Oil Port Joint Tightening Torque Table”. If necessary, it can be executed according to about 1.5 times the specified torque in the torque table.

④ If the joint body follows the rotation when the lock nut is tightened, it is necessary to fix the joint body with a wrench while tightening the lock nut.

The above are the general steps for installing adjustable adapters.

The following is a photo of an example where sealing failure was caused by not following the proper way.

From the above photo, you can see that the washer has been severely deformed, which will causes the O-ring to be squeezed and damaged, finally resulting in seal failure. The analysis shows that the reason for this phenomenon is that the wrench was used to tighten the adapter body directly in the second step of the installation method mentioned above. Since the outer side of the washer has been fixed, when the adapter body was tightened by wrench, the inner hole of the washer is squeezed downwards by the thread on the adapter body, leading to the washer changing into a funnel-shaped.

In summary, we must follow the steps specified in this method when installing such adapters to avoid installation failure.

Leave a Reply

Want to join the discussion?Feel free to contribute!